Overview

Custom wet press molded pulp inserts and box are ideal for packaging lightweight products like cosmetics, gift packaging, food, electronics, wine and toys products. Popular for ensuring products are held in place to withstand movement, wet press molded pulp inserts are incredibly lightweight and are custom formed to your products to ensure a tight fit within almost any packaging type. The surface features a glossy surface finish adding a higher perceived value to the unboxing experience for your customers.

Product description

Material: Sugarcane fiber/bagasse

Logo: Embossed

Packing: stacked, poly bag, export carton (pallet available)

Sample tooling & sample lead time: 8 days

Sample mold lead time: 12 days

Production lead time: 15 days

Product advantages

1. 100% biodegradable & compostable molded fiber insert packaging.

2. Sustainable, environmentally, eco-friendly and recyclable.

3. Molded pulp products made from natural fiber-based, renewable resources.

4. Anti-static, protective and cushioning.

5. Waterproof & oil resistant available.

6. Professional molded pulp paper products Chinese manufacturers.

7. Customization color, high quality performance.

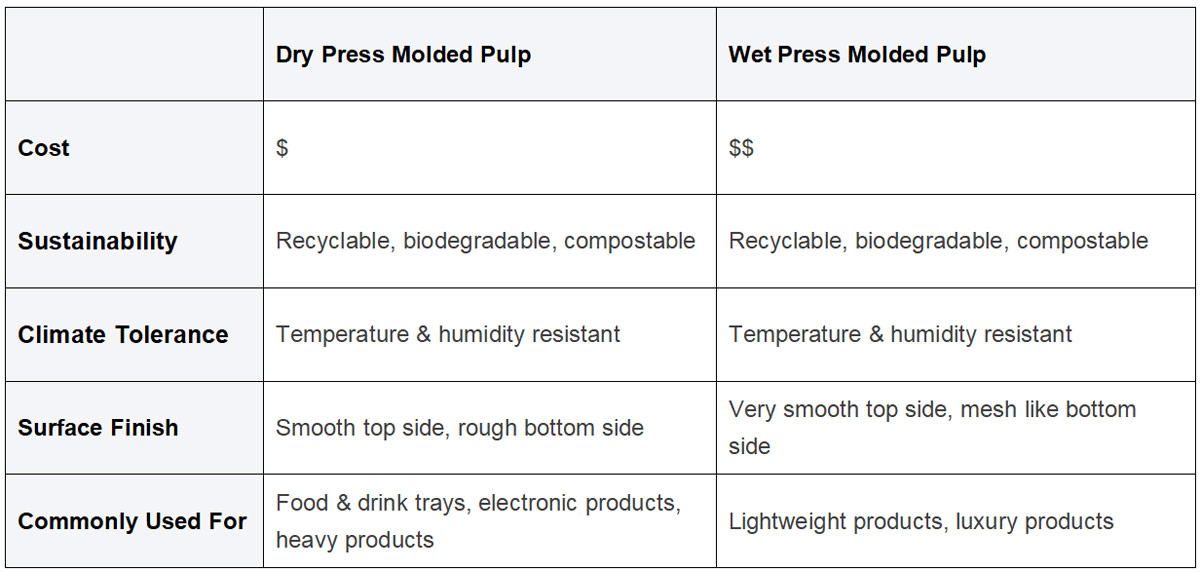

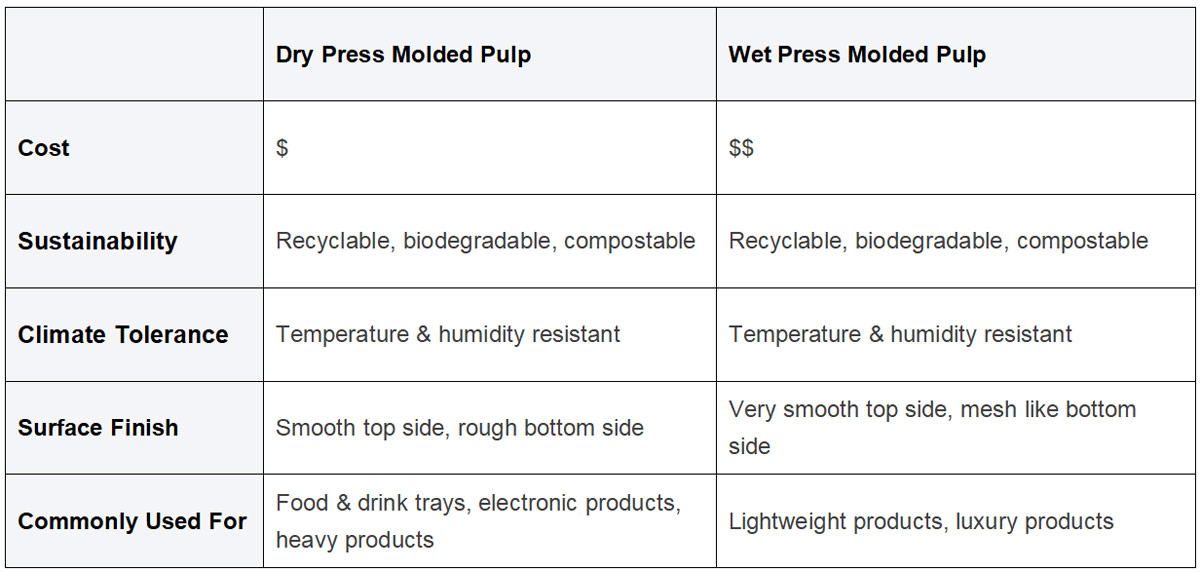

Drypress/Wetpress Comparison