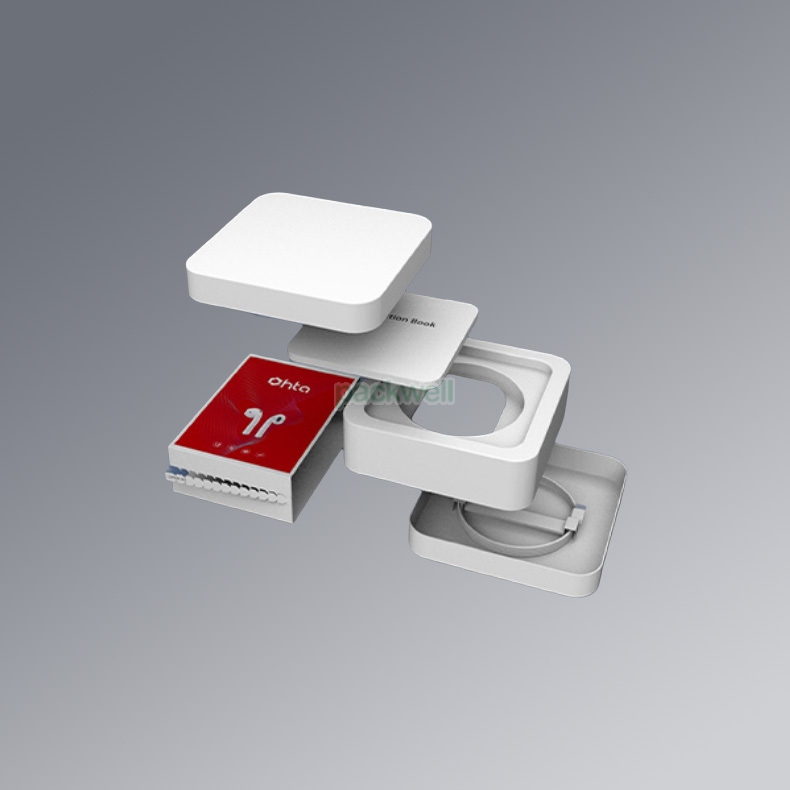

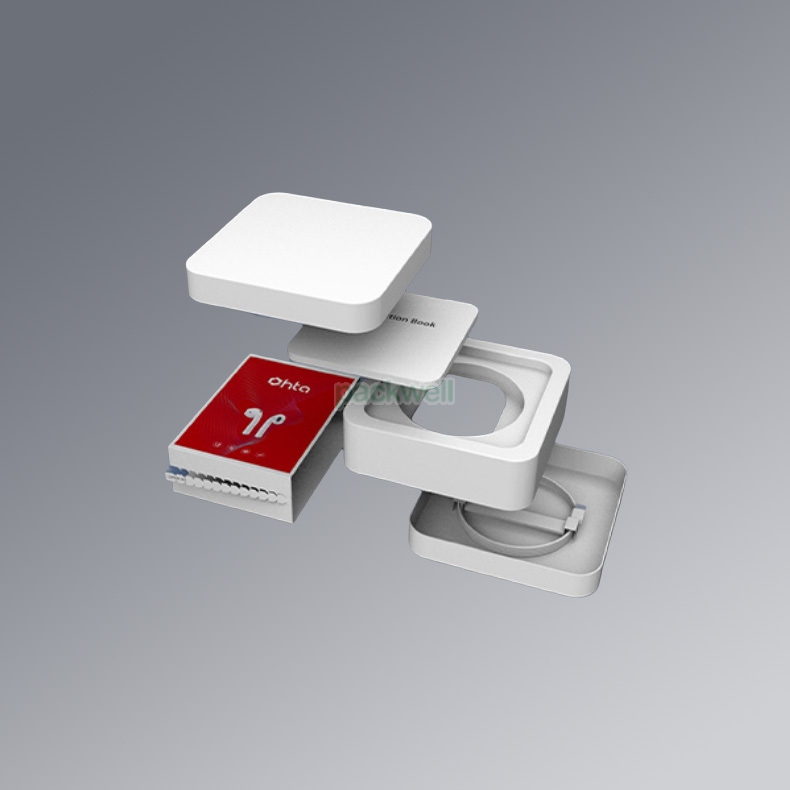

Overview

Processed molded pulp refers to any molded pulp box inserts that has gone through any additional processes such as dying, coating or hot pressing. This gives you the opportunity to customize your box inserts with molded pulp and creates more high quality results when used for product packaging. Available for all types of molded pulp inserts, processed molded pulp offers brands the opportunity to enhance the unboxing experience through detailed customization.

Product description

Material: Sugarcane fiber/bagasse

Size: Custom made

Packing: stacked, into polybag, carton possible

Sample tooling & sample lead time: 8 days

Mass production mold lead time: 12 days

Production lead time: 25 days

Product advantages

1. Sustainable & Recyclable Plant Fiber and Pulp Molded.

2. Additional processes like Dyeing Color, Print, Hot Stamping, Dual Layer; Edge Treatment, Emboss and Deboss.

3. Eco-friendly dyeing color, color could be customized or specified; more than 95% close to Pantone color.

4. High quality, smooth appearance.

5. Superior protective, anti-shock.

6. 100% recyclable, renewable resources.

7. Professional molded pulp paper products manufacturers China.

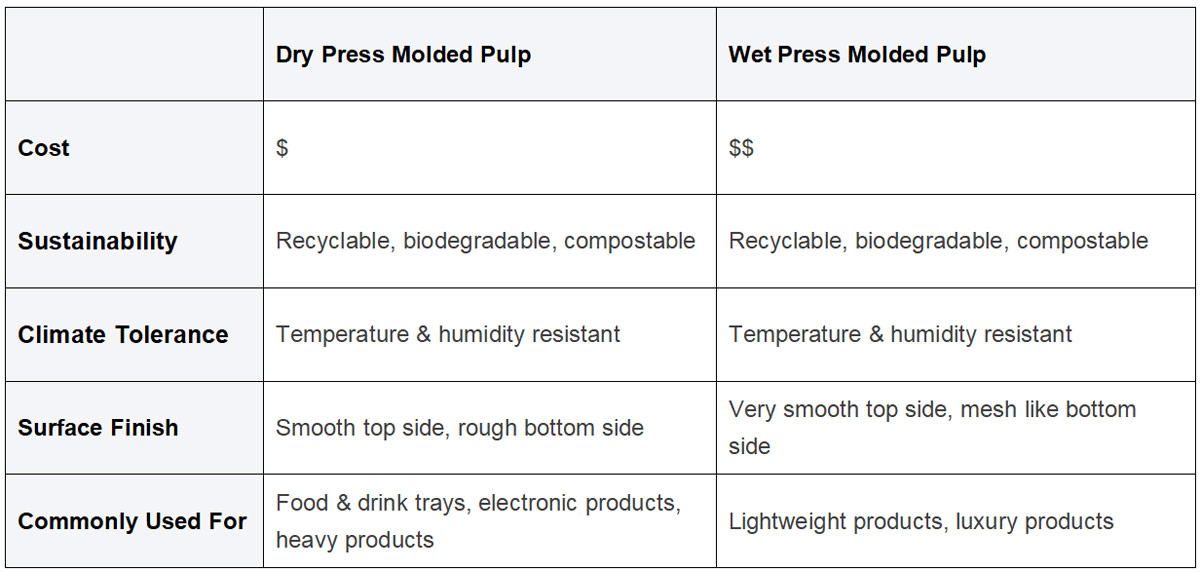

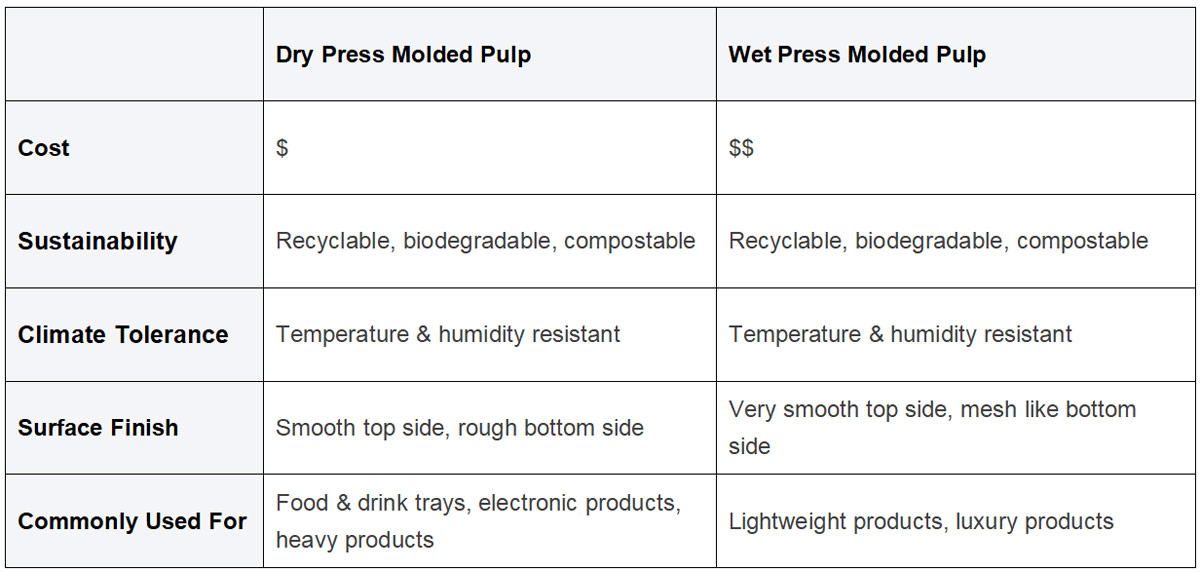

Drypress/Wetpress Comparison

Second Process Options

Second Process Options