Overview

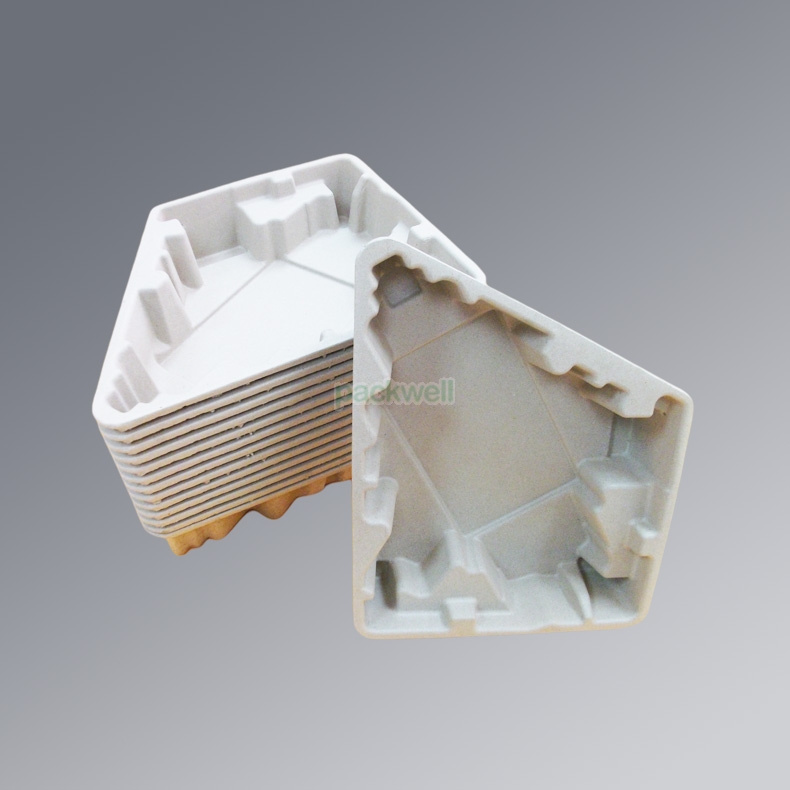

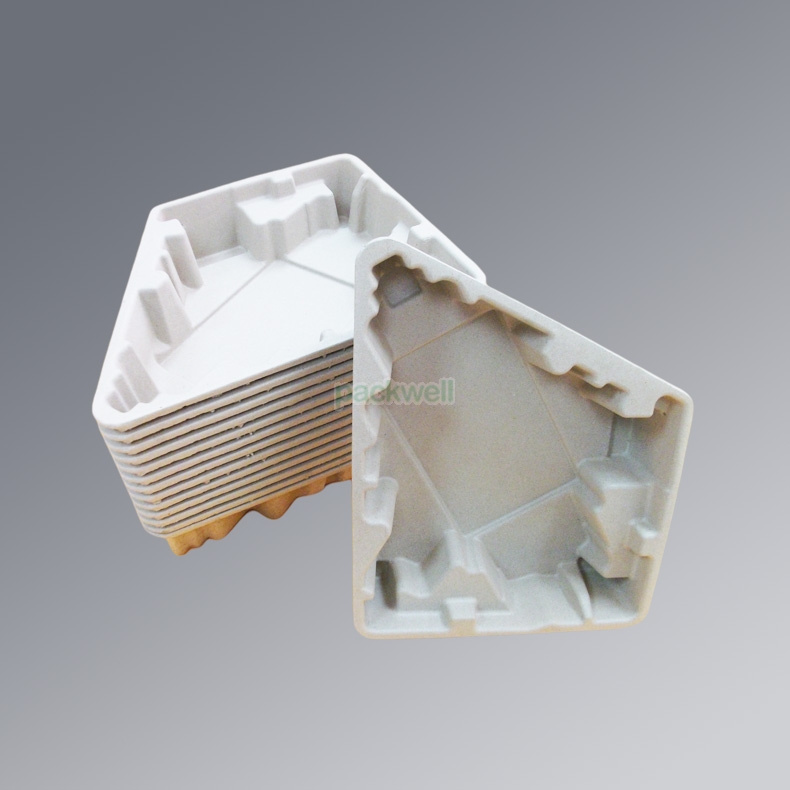

Custom dry press molded pulp inserts are 100% recyclable and provide exceptional support and protection to fragile and heavy weight products. Popular for packaging e-commerce products, electronics and certain food products, these inserts are shaped to your product, providing exceptional edge protection and structure which minimizes the risk of damage during shipping. Dry press molded pulp inserts are available in transfer molded pulp which features a polished surface ideal for creating protective custom box inserts that still adds to the unboxing experience of your products.

Product description

Material: recyclable paper pulp

Size: custom made

Packing: stacked, into polybag, carton possible

Sample tooling &sample lead time: 8 days

Mass production mold lead time: 12 days

Mass production lead time: 15 days

Product advantages

1. Recyclable paper pulp, no pollutions

2. Customization color, high quality performance

3. China suppliers, best services

4. Biodegradable eco-friendly molded paper pulp for products inserts packaging

5. Professional molded pulp paper products Chinese manufacturers.

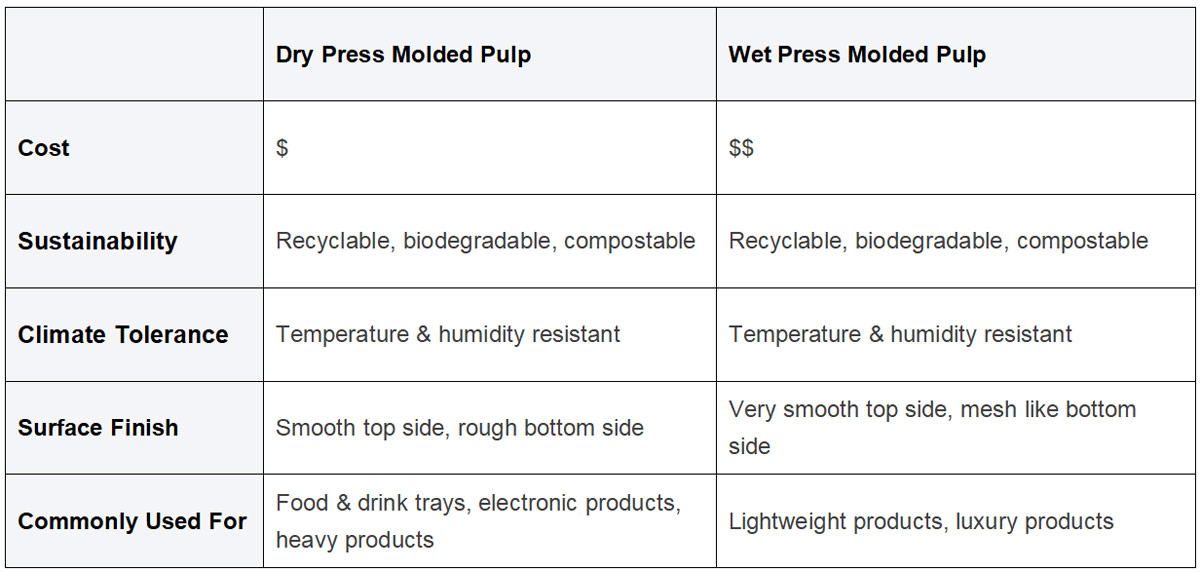

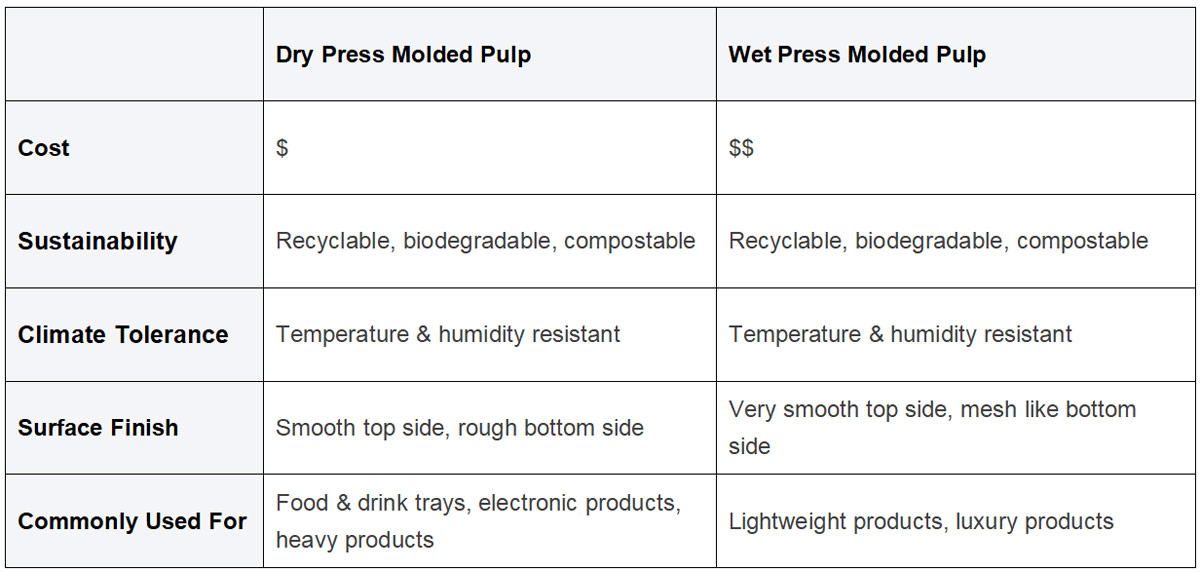

Drypress/Wetpress Comparison